Affordable seedball disseminator

The Design Challenge

The problem that I am tackling is to be able to affordably disseminate seedballs, an innovative solution to deforestation, in semi-arid, remote regions of Kenya, while taking into consideration the economic challenges faced by those who live in such regions.

Summary of Research

I first started by characterizing my target audience in order to come up with a Design Brief. The target audience is those who need to reforest a large squarage of land or are concerned for the environment (eco-fans) and are willing to help in distributing seeds for the purpose of restoration.

The design challenge is to design an affordable seedball dispenser that is able to accurately and at scale, disseminate seedballs in a suitable area where they are most needed and are likely to grow. During the brainstorming process, I decided that an animal based dispenser would offer many advantages such as wide coverage, low cost and most importantly increased affordability.

I settled on using camels, the rugged nomadic vehicles of the desert, to carry seedballs on their back. I devised a mechanism to be able to disperse the seedballs regularly and in a controlled fashion on a camel, without requiring expensive electronic seeders. I figured that if I was able to tap into the oscillatory motion of the camel, it would allow for a mechanism that relies on the walking gait of the animal to disperse the seeds periodically(after controlled intervals).

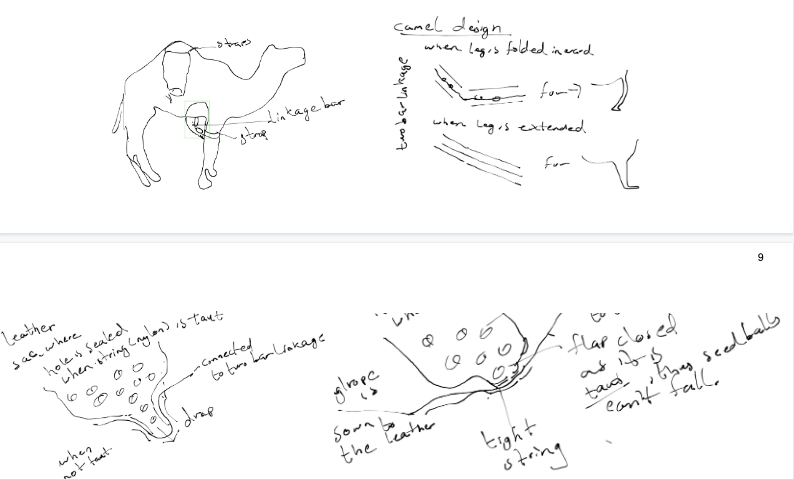

Initial sketches

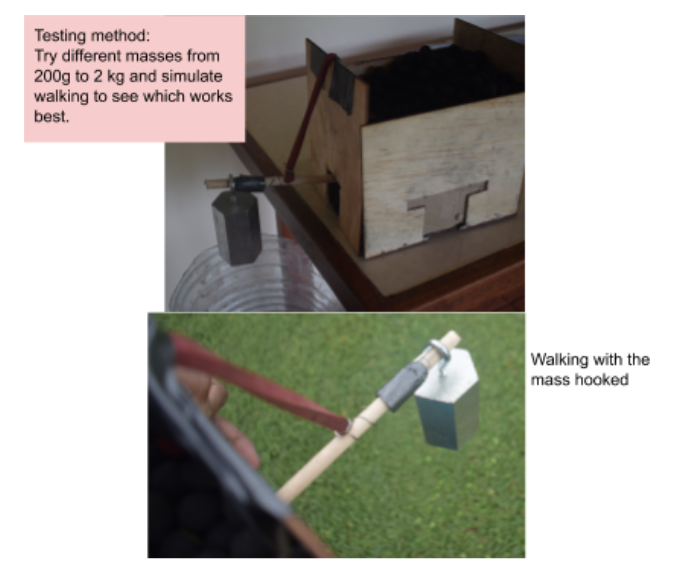

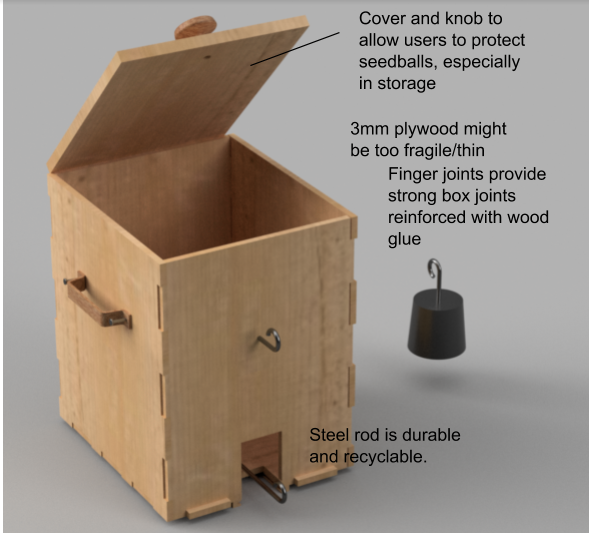

I decided on a box to hold the seeds as it would provide structure and durability. I also designed a mass oscilating system that instead of linking dire ctly to the leg movement of the camel, it would instead rely on the agitation of the whole body caused by the movement itself. The mass would swing freely on a rod and would be counteracted by an elastic (spring) force. The agitation would cause the seedballs to fall from the hole.

I also used CAD software for modelling.

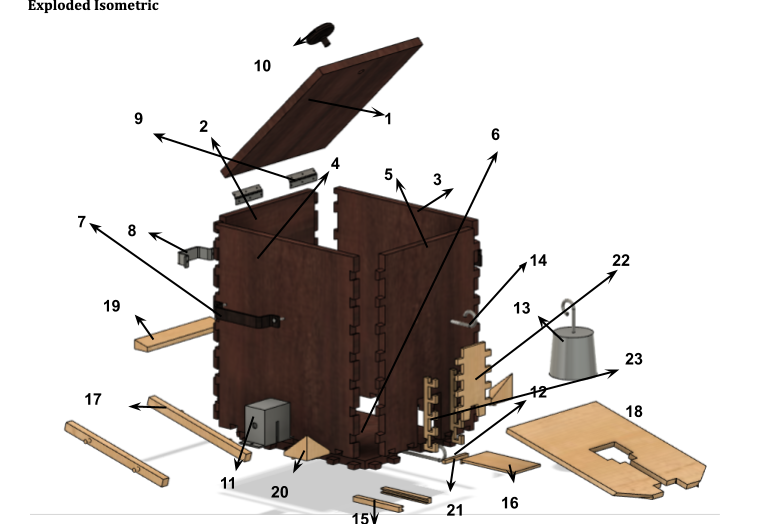

Bill of Materials

| Label | Material component | Quantity |

| 1 | Top | 1 |

| 2 | Back | 1 |

| 3 | Side a | 1 |

| 4 | Side b | 1 |

| 5 | Side d | 1 |

| 6 | Bottom | 1 |

| 7 | Handle | 2 |

| 8 | Attachment to Camel – Rope brackets | 2 |

| 9 | 3mm Butt Hinge (Purchased as stock material) | 2 |

| 10 | Knob (Purchased as stock material) | 1 |

| 11 | Agitator Box | 1 |

| 12 | Agitator rod | 1 |

| 13 | Offset Weight | 1 |

| 14 | Elastic Band Hook | 1 |

| 15 | Bottom slider rails | 2 |

| 16 | Bottom slider | 1 |

| 17 | Side rail for ramp | 2 |

| 18 | 15˚ 3mm plywood ramp | 1 |

| 19 | Back rail for ramp | 1 |

| 20 | Corner Wedge | 2 |

| 21 | Bottom slider block | 1 |

| 22 | Adjustment gate | 1 |

| 23 | Adjustment L-hooks | 2 |

| 00 | ¼ inch nails | 7 |