Biodegradable Food Packaging

The Design Challenge

Hundreds of tons of food packaging are thrown away every year – ending up in our cities, parkes, oceans and even (most frighteningly) our bodies. I am endeavoring to understand the multifaceted problem of sustainable food packaging at every stage and design a package that I can stomach eating out of.

Summary of Research

Kombucha packaging:

Kombucha is a symbiotic culture of fungi and bacteria. It forms as a mulie-layered membrane on the surface of the ‘tea’ in which it is grown. It is edible according to Art of Fermentation and it is compostable. When wet, it becomes sticky. It smells weird but when dried properly this odor disappears.

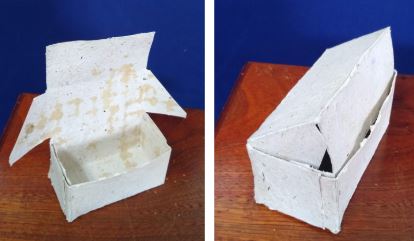

The traits that were most exciting to me about Kombucha leather were that it is edible and that it becomes sticky when wet. This stickiness opened the door for designs like those pictured below.

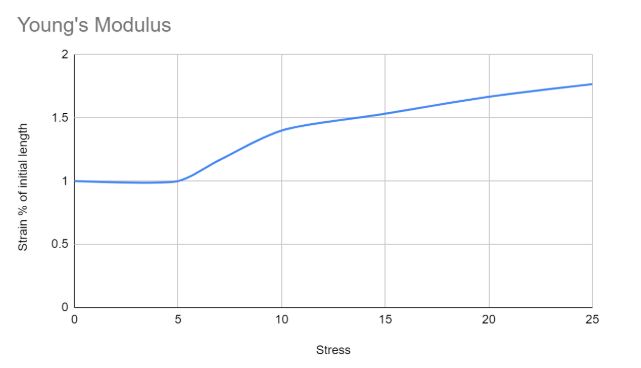

The leather is also very difficult to tear. This is promising because large volumes of food, or heavy foods, could be stored in it and handled without worry. One of the appeals of plastic is its high tensile strength.

Recycled Paper Packaging

Reused Newspapers are often used by informal businesses to sell small quantities of dried foods. However, the legality of using something like that is complicated because of the possibility of the paper having been touched and contaminated by human hands. Paper is impossible to wash for obvious reasons, but it is relatively easy to recycle and any bacteria or viruses can be killed during this process.

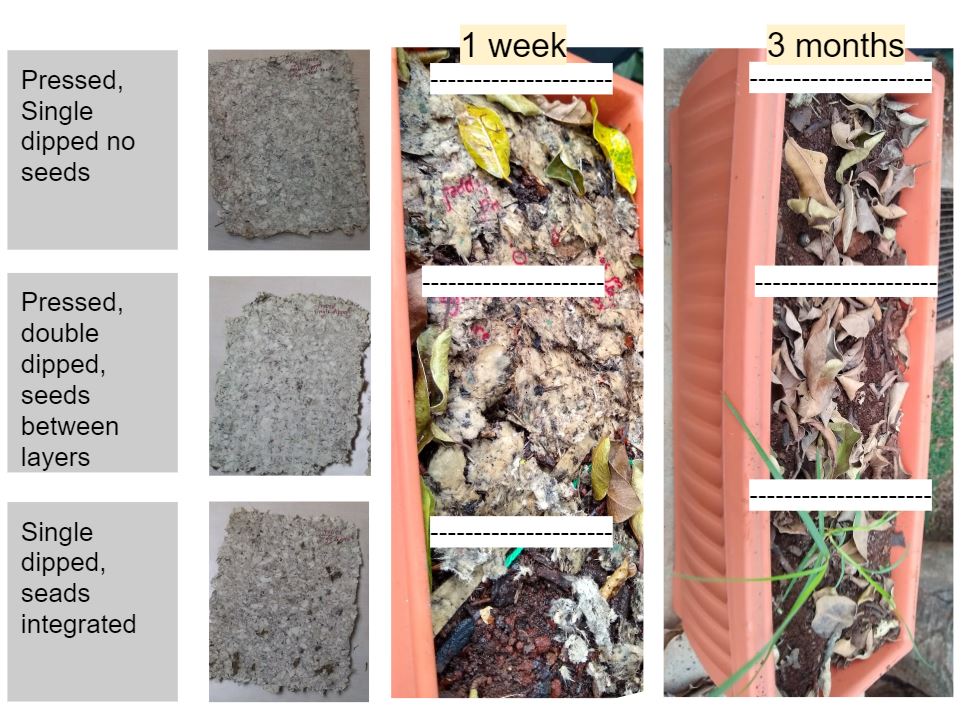

The traits that were most exciting to me about recycled paper were how variable it is in thickness, the ready availability of the raw materials, and the potential to integrate other small substances (like seeds) into the material.

The process of papermaking is ancient and fascinating. At a small scale at ISK the step where to shred the paper, broil it for ten minutes (killing all bacteria and breaking down the paper), cast the paper, roll it flat and then set it to dry. Usually, paper is not broiled but instead left to soak for a prolonged period – I figured out the broiling myself and it works quite similarly.

The most exciting thing about the paper was the possibility of integrating seeds. This presented some design challenges. Naimingly, the seeds would germinate if left in the paper while it airdryed. Thankfully, the process of pressing the paper also squeezes most of the water out. However, when pressing the paper flat bigger seeds get squished. Using smaller seeds solves the problem but limits what we can use the paper to grow.